Glass engineering Designing and making Photochromic Glass

Abstract

“There’s only one material on earth that won’t stick to molten glass and that’s platinum.”

Content

How to make small batches of specialty glass with minimal equipment.

Good overview glass engineering book from 1920 (how to choose ingredients):

http://www.wallace-venable.name/Glass/bastow_American_Glass_Practice.pdf

Alumina melting dish on eBay:

https://www.ebay.com/itm/Crucibles-Melting-Dishes-Ceramic-4-Size-Casting-Torch-Melt-Jewelry-Gold-Silver/291595276663

Source of kiln paper, mold release, molds, glass fusing supplies:

https://www.delphiglass.com/

Paragon Quickfire kiln:

https://www.sheffield-pottery.com/default.asp

Case of 12 insulating fire bricks:

ebay.com

Graphite mold:

ebay.com

Relevant patents for photochromic recipes:

https://docs.google.com/viewer?url=patentimages.storage.googleapis.com/pdfs/US2515936.pdf

https://docs.google.com/viewer?url=patentimages.storage.googleapis.com/pdfs/US3548060.pdf

https://patentimages.storage.googleapis.com/b1/76/10/d4bd570c1a161c/US4374931.pdf

https://patentimages.storage.googleapis.com/26/71/a3/481dc009490fe6/US2515275.pdf

https://patentimages.storage.googleapis.com/a1/cf/ef/a11d9037375914/US2684911.pdf

https://patentimages.storage.googleapis.com/0c/b0/d2/d53ec9e6fd478a/US3548060.pdf

https://patentimages.storage.googleapis.com/3d/31/3b/0b3bc6c18b7ef3/US3419370.pdf

Glass colors:

https://www.compoundchem.com/wp-content/uploads/2015/03/The-Chemistry-of-Coloured-Glass.png

The article “Glass Engineering: Designing and Making Photochromic Glass” provides a practical guide for creating small batches of specialty glass, specifically photochromic glass, using minimal equipment. It references a 1920 glass engineering book for ingredient selection and offers resources for necessary materials and equipment, such as alumina melting dishes, kilns, and molds. Additionally, the article includes links to relevant patents detailing photochromic glass recipes, which can serve as valuable references for understanding the chemical formulations involved.

Photochromic glass contains molecules that change structure when exposed to ultraviolet (UV) light, causing the glass to darken. When the UV light is removed, the molecules revert to their original structure, and the glass returns to its clear state. This reversible reaction is commonly utilized in applications like photochromic lenses, which darken in sunlight and clear up indoors.

For those interested in the practical aspects of making photochromic glass, the article includes a video demonstration that outlines the process and equipment involved.

In summary, the article serves as a resource for enthusiasts and professionals interested in the engineering and production of photochromic glass, offering historical context, practical guidance, and technical references to support small-scale manufacturing endeavors.

The Fascinating World of Photochromic Glass: From Design to Creation

Photochromic glass, the kind that transitions between clear and tinted depending on exposure to ultraviolet (UV) light, has captivated scientists and innovators since its invention. This specialty glass combines cutting-edge chemistry with intricate glass engineering, resulting in practical applications like photochromic lenses in eyewear. But how is it made? Let’s explore the journey of crafting photochromic glass—a process steeped in science, skill, and a dash of alchemy.

Understanding Photochromic Glass

At the heart of photochromic glass lies a fascinating chemical mechanism. Embedded within the glass matrix are photochromic molecules, such as silver halides or organic compounds. When exposed to UV light, these molecules undergo a structural change, absorbing light and causing the glass to darken. Once the UV light is removed, the molecules return to their original state, and the glass clears up. This reversible reaction is the key to photochromic glass’s functionality, making it a marvel of material science.

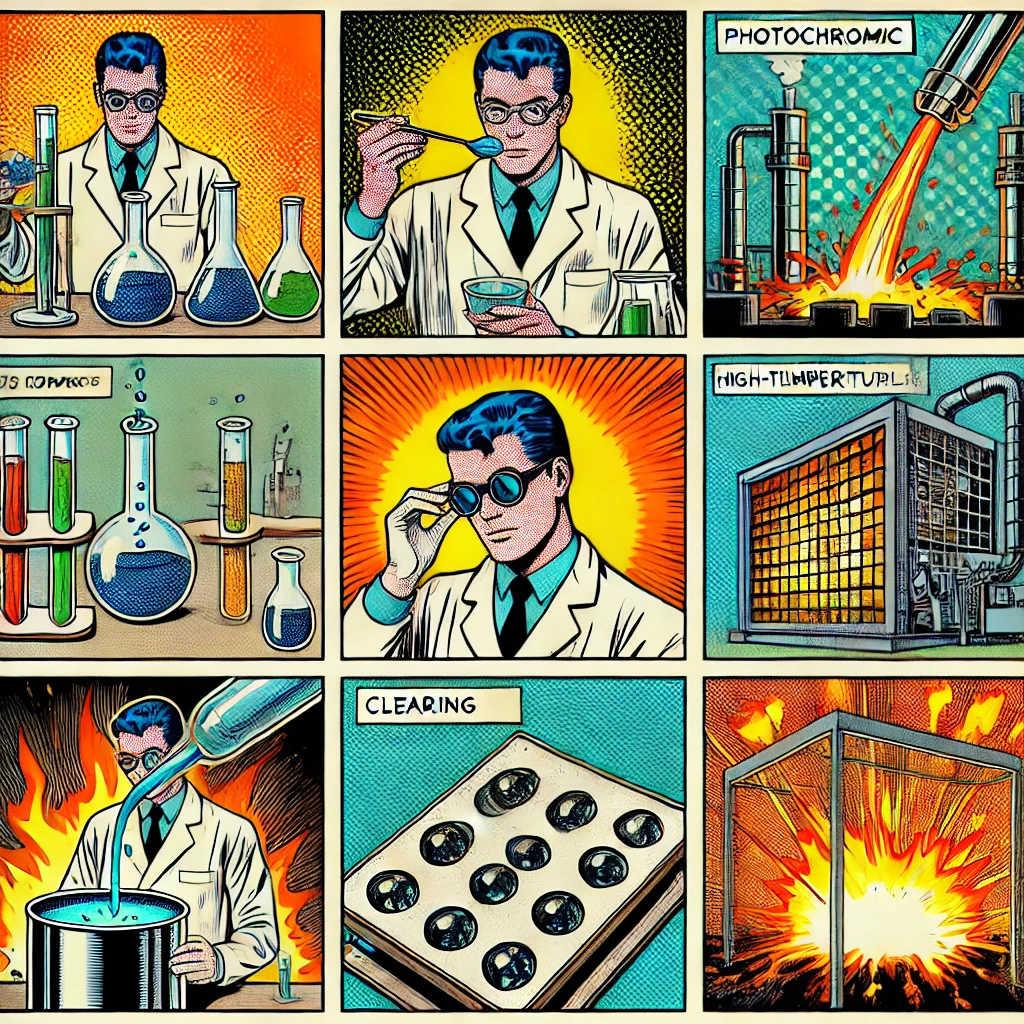

Designing Photochromic Glass: A Step-by-Step Process

1. Ingredient Selection: The journey begins with choosing the right ingredients. Raw materials like silica, alumina, and specialized photochromic compounds are carefully selected based on their optical and thermal properties. Historical resources, such as early 20th-century glass engineering guides, often inspire modern recipes.

2. Mixing and Melting: The ingredients are thoroughly mixed to ensure uniformity and then placed in a high-temperature kiln. The kiln, often operating at temperatures exceeding 1,400°C (2,552°F), melts the mixture into a viscous, glowing liquid. The high temperatures ensure that the photochromic compounds are evenly distributed throughout the molten glass.

3. Shaping and Cooling: The molten glass is poured into molds to form desired shapes—be it lenses, panes, or decorative objects. The glass then undergoes a controlled cooling process known as annealing. This step relieves internal stresses, ensuring the glass is durable and free of imperfections.

4. Testing and Tuning: Once the glass has cooled, it is tested for its photochromic properties. This involves exposing it to UV light and measuring its transition speed and optical clarity. Adjustments may be made to refine the composition and achieve the perfect balance of performance and aesthetics.

Applications of Photochromic Glass

Photochromic glass is not just for sunglasses. Its ability to adapt to changing light conditions makes it ideal for a variety of applications:

- Architectural Glass: Used in smart windows that reduce glare and improve energy efficiency.

- Automotive: Deployed in car windshields to enhance visibility and reduce UV exposure.

- Medical Devices: Incorporated into specialty eyewear for patients with light sensitivity.

The Future of Photochromic Technology

Innovations in photochromic materials continue to expand their possibilities. Researchers are exploring faster transitions, enhanced durability, and integration with other technologies like electrochromic systems. The potential for customization also grows, with options for different colors and patterns to cater to aesthetic preferences.

A Glassmaking Art

Crafting photochromic glass is as much an art as it is a science. From the precise selection of ingredients to the mastery of high-temperature glassblowing, every step in the process reflects human ingenuity. As the demand for adaptive and sustainable materials rises, photochromic glass stands out as a testament to the brilliance of modern engineering.