How is Gold Leaf made

Gold leaf is made in specialized workshops and factories around the world. The process involves skilled craftsmanship and is often deeply rooted in tradition. The multiple stages require precision and expertise:

- Melting: Gold is melted and alloyed with other metals (if necessary) to achieve the desired karat.

- Rolling: The gold is rolled into thin sheets using specialized rolling mills.

- Beating: Sheets are beaten between layers of parchment paper or plastic using hammers or mechanical presses until they reach the desired thinness.

- Cutting and Packaging: The thin gold leaf is cut into squares, stacked, and packaged into books or rolls.

The process of making gold leaf is a highly specialized craft that requires precision, patience, and skill. The traditional methods have been refined over centuries and remain largely the same, though some modern techniques have streamlined parts of the process. Here’s an in-depth explanation:

1. Gold Preparation

- Melting the Gold:

- Pure gold is melted in a crucible at extremely high temperatures, often exceeding 1,000°C (1,832°F).

- Other metals like copper or silver may be added to create gold alloys of varying karat values (e.g., 22k, 23k).

- Casting:

- The molten gold is poured into molds to form small bars or ingots, which are easier to work with in subsequent steps.

2. Rolling the Gold

- Initial Rolling:

- The gold ingot is rolled through heavy rollers to flatten it into a thin sheet, typically about 1/1000th of an inch thick.

- Annealing:

- The gold sheet is periodically heated to soften it, preventing cracking as it is repeatedly rolled thinner.

- Final Rolling:

- The sheet is rolled into a ribbon of consistent thickness, preparing it for the beating stage.

3. Cutting into Squares

- The gold ribbon is cut into smaller squares, known as “gold leaf squares,” which are layered between sheets of parchment paper or other separating materials.

4. Beating the Gold

- Traditional Beating:

- The squares are placed between layers of “goldbeater’s skin,” a durable and elastic material traditionally made from ox intestines.

- Using hammers or mechanical presses, the gold is pounded repeatedly until it becomes paper-thin (as thin as 0.1 microns).

- Modern Techniques:

- Many workshops now use precision machines to automate this process, ensuring uniform thickness.

5. Cutting and Packaging

- Trimming:

- The ultra-thin gold leaf is trimmed to size, often 3 3/8 inches by 3 3/8 inches for standard books.

- Stacking:

- Sheets are stacked in groups of 25 (called a “book”) and interleaved with tissue paper to prevent sticking.

- Packaging:

- The books are packaged for sale, often labeled by karat, size, and type (e.g., loose or transfer leaf).

6. Types of Gold Leaf

- Loose Gold Leaf:

- Free-floating gold leaf that must be handled with special tools like a gilder’s tip.

- Transfer (Patent) Gold Leaf:

- Gold leaf adhered to a backing paper for easier application, especially on vertical or overhead surfaces.

- Ribbon Leaf:

- Gold leaf provided in long continuous rolls for seamless application on moldings and architectural details.

Quality Control

- Gold leaf undergoes rigorous quality checks to ensure uniformity, durability, and brilliance. Any inconsistencies are removed before packaging.

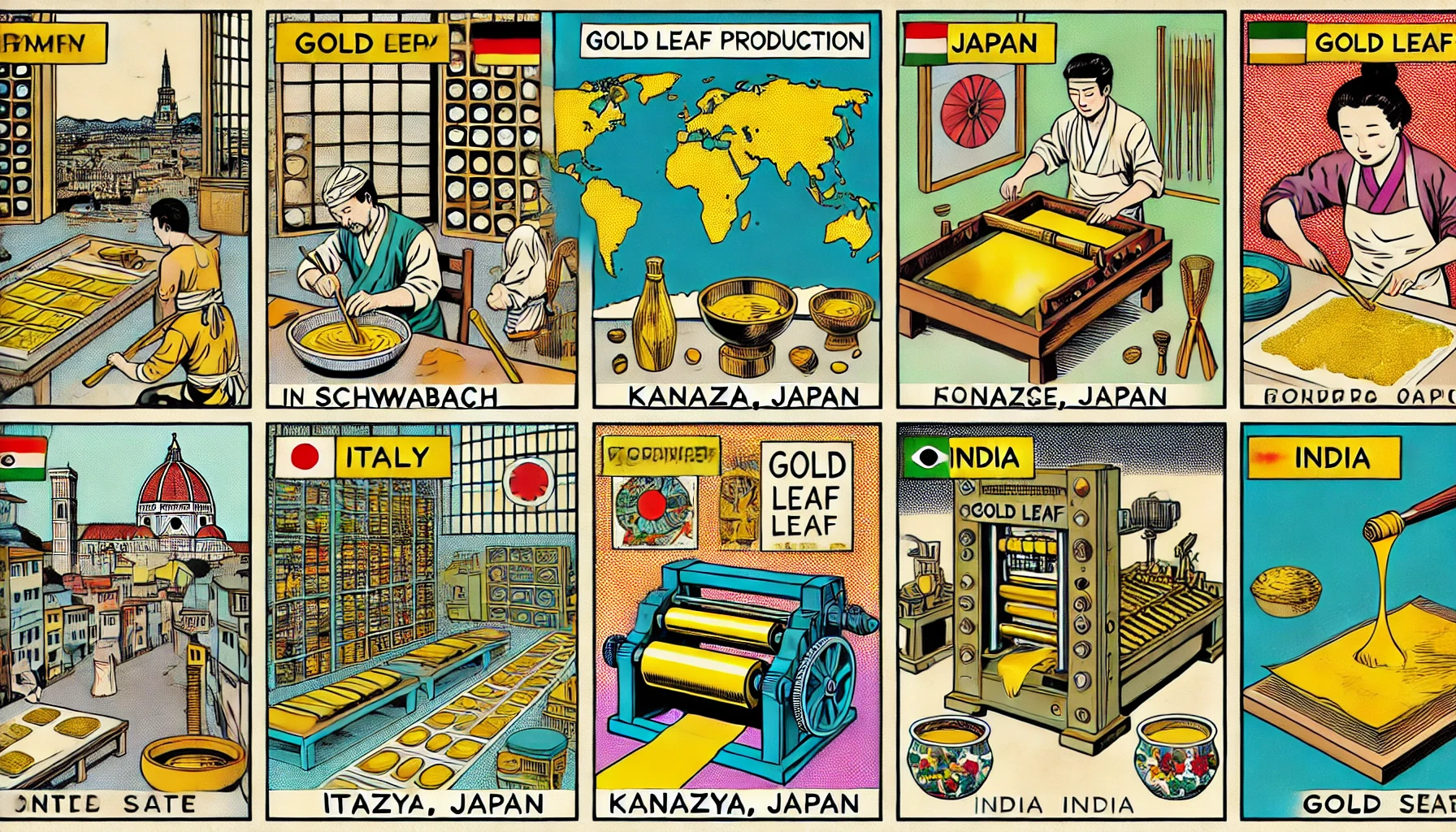

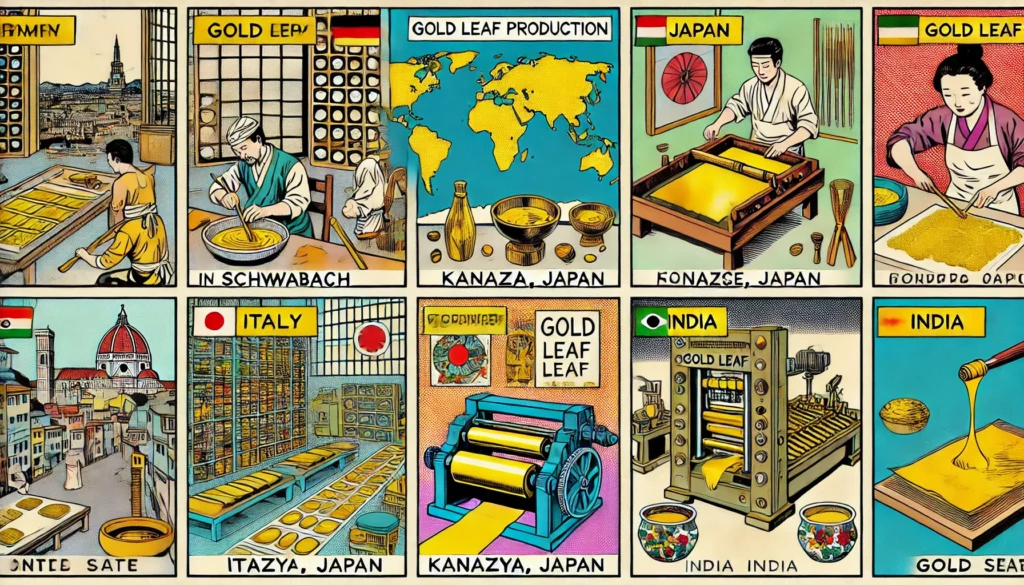

Artisanal and Regional Variations

- Schwabach, Germany:

- Known for its artisanal methods, Schwabach workshops still use traditional tools and techniques for their high-quality gold leaf.

- Kanazawa, Japan:

- Famous for creating some of the thinnest gold leaf in the world, often used for cultural crafts and culinary purposes.

- Florence, Italy:

- Renowned for gold leaf used in art restoration and ornate Renaissance frames.

Modern Advancements

- While the core of gold leaf production remains artisanal, some steps, like rolling and beating, have been enhanced by machinery to improve consistency and efficiency. However, the thinness and delicacy of gold leaf still demand manual skill for handling and finishing.