Where is Gold Leaf made

Gold leaf is made in specialized workshops and factories around the world. The process involves skilled craftsmanship and is often deeply rooted in tradition. Below are the key regions known for gold leaf production:

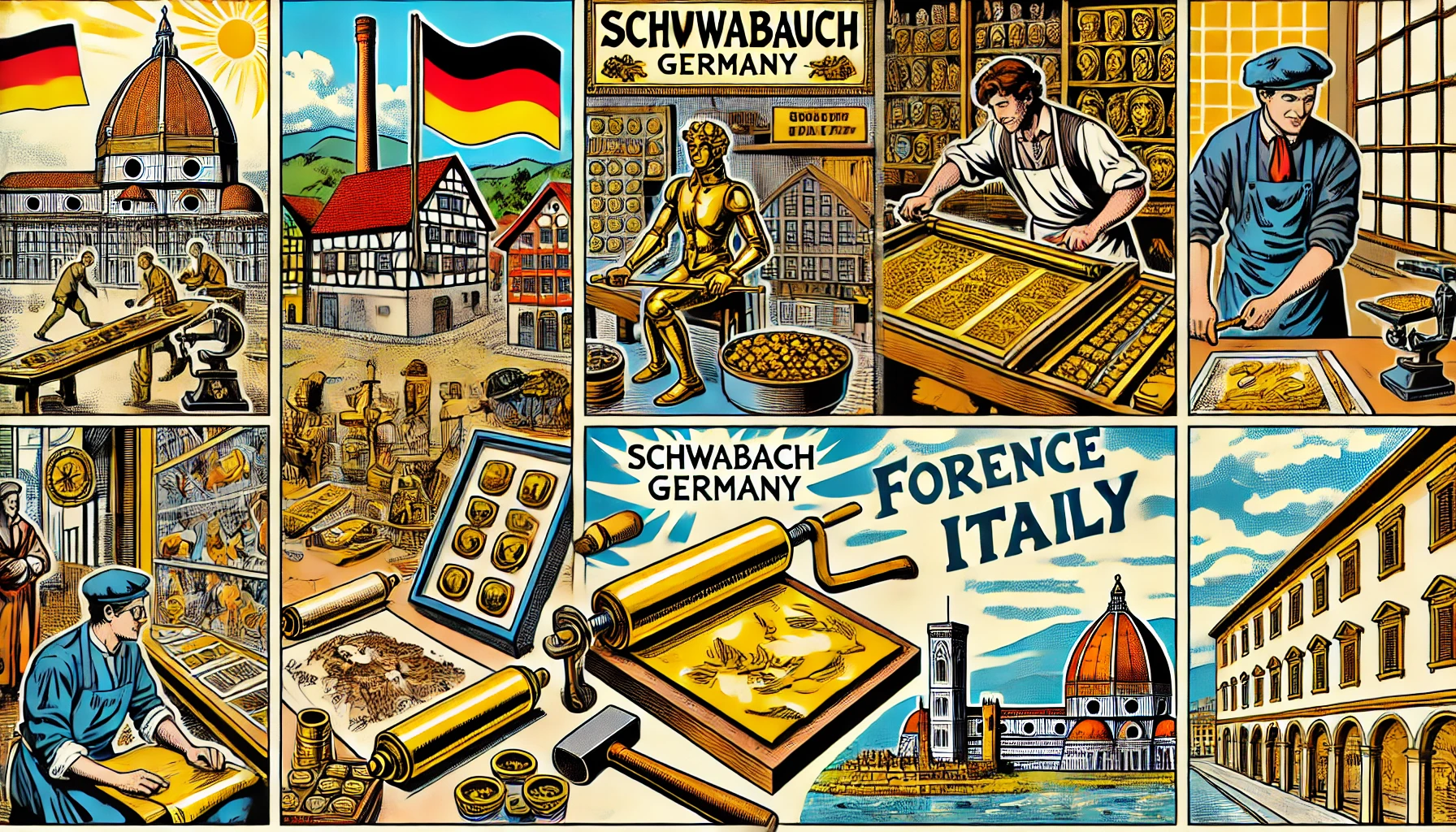

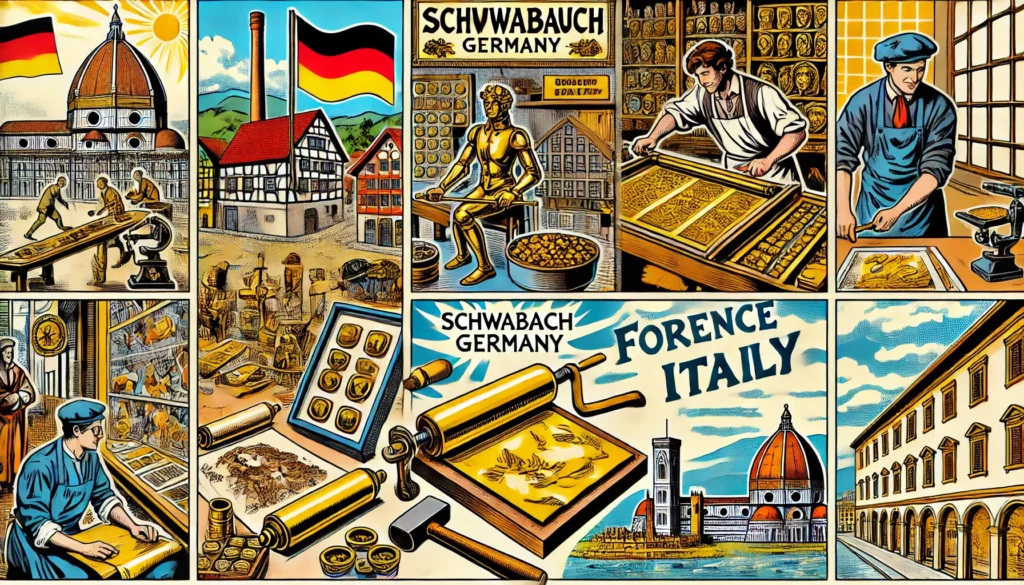

1. Europe

Germany

- Eytzinger: One of the most renowned producers of gold leaf, based in Schwabach, Germany. The region has been a hub for gold leaf manufacturing since the Middle Ages.

- Specializes in high-quality leaf used for gilding frames, architectural details, and artwork.

Italy

- Florence and Milan: Italy is famous for its high-quality gold leaf, often used in art restoration and luxury goods.

- Italian gold leaf is known for its vibrant color and smooth application.

France

- Dauvet: A historic producer of gold leaf in France, known for crafting delicate sheets for fine art, religious artifacts, and culinary applications.

2. Asia

Japan

- Kanazawa: A city in Japan renowned for its gold leaf production, with techniques dating back over 400 years.

- Kanazawa produces ultra-thin gold leaf used in traditional crafts, decorations, and even food.

India

- Known for producing gold leaf for decorative and cultural uses, such as in religious artifacts and traditional crafts.

- Often used in large quantities for ceremonial purposes.

China

- A significant producer of both genuine and imitation gold leaf, catering to a global market.

- Often used in mass-produced decorative items and crafts.

3. United States

- Gold Leaf and Metallic Powder Co. (GLMPC): Based in the U.S., this company manufactures gold leaf and related products for art, restoration, and architectural purposes.

- American producers focus on both traditional craftsmanship and modern techniques.

How Gold Leaf Is Made

The process involves multiple stages, requiring precision and expertise:

- Melting: Gold is melted and alloyed with other metals (if necessary) to achieve the desired karat.

- Rolling: The gold is rolled into thin sheets using specialized rolling mills.

- Beating: Sheets are beaten between layers of parchment paper or plastic using hammers or mechanical presses until they reach the desired thinness.

- Cutting and Packaging: The thin gold leaf is cut into squares, stacked, and packaged into books or rolls.

Gold leaf production is an intricate and labor-intensive process that combines ancient techniques with modern refinements. Below is a detailed breakdown of the steps involved in making gold leaf, including variations based on different processes:

1. Gold Preparation

- Melting:

- Pure gold is melted in a crucible at temperatures exceeding 1,000°C (1,832°F).

- Alloys may be added to achieve different karat values, such as 22k or 23k, for color or strength variations.

- Casting:

- The molten gold is poured into molds to create small bars or ingots, making it easier to handle in subsequent steps.

2. Rolling

- Initial Rolling:

- The gold ingot is rolled through heavy mechanical rollers to flatten it into a thin sheet, typically around 0.1–0.2 mm thick.

- Annealing:

- During rolling, the gold is periodically annealed (heated) to soften it. This prevents cracking and maintains malleability.

- Final Rolling:

- The sheet is further thinned to prepare it for the beating process. This step ensures a uniform thickness and smoothness.

3. Cutting into Squares

- The flattened gold sheet is cut into small squares, which are the precursors to individual gold leaf sheets.

- These squares are then stacked and prepared for beating.

4. Beating (Goldbeating)

Traditional Beating:

- Stacking with Goldbeater’s Skin:

- Gold squares are layered between sheets of goldbeater’s skin, traditionally made from ox intestines. This material is elastic and durable, helping to distribute the force evenly.

- Hand Beating:

- Artisans manually hammer the stack using specialized hammers, gradually thinning the gold to a fraction of a micron.

- Progressive Beating:

- The beating process occurs in stages, with the gold being re-stacked and repositioned to ensure even thinning.

Modern Mechanical Beating:

- In industrial settings, mechanical presses are used to beat the gold uniformly, streamlining the process while maintaining precision.

5. Final Trimming

- Smoothing and Flattening:

- The beaten gold is smoothed and inspected for uniformity.

- Cutting to Size:

- The ultra-thin gold leaf is trimmed to standard sizes, typically around 3 3/8 inches (8.57 cm) square for individual sheets.

6. Packaging

- Stacking into Books:

- Gold leaf sheets are interleaved with tissue paper to prevent sticking and are stacked in groups of 25, known as a “book.”

- Labeling and Branding:

- Each book is labeled with details such as karat value, thickness, and type (loose leaf or transfer leaf).

Types of Gold Leaf

- Loose Gold Leaf:

- Individual sheets not attached to a backing. Requires delicate handling and is used for flat surfaces.

- Transfer (Patent) Gold Leaf:

- Gold leaf attached to a backing paper for easier application, especially on vertical or overhead surfaces.

- Ribbon Leaf:

- Long rolls of gold leaf for seamless application on moldings or extended surfaces.

Regional Techniques

- Schwabach, Germany:

- Renowned for preserving traditional goldbeating methods and producing some of the finest gold leaf.

- Kanazawa, Japan:

- Known for creating ultra-thin gold leaf, used in traditional crafts, culinary applications, and cosmetics.

- Florence, Italy:

- Specializes in producing gold leaf for art restoration and ornate decorative applications.

Quality Control

- Every sheet of gold leaf is inspected for uniformity in thickness, smoothness, and color.

- Sheets that do not meet the quality standards are discarded or reprocessed.

Modern Advancements

- The introduction of mechanical rollers and presses has significantly reduced labor intensity while ensuring consistent quality.

- Synthetic materials are sometimes used as alternatives to goldbeater’s skin, improving sustainability and efficiency.

This meticulous process is what allows gold leaf to be so thin, durable, and versatile.